Rigging Supplies and Equipment

Founded in 1947

Over 75 Years of Experience

Free Quotes

Your One-Call Rigging Equipment Headquarters

When you need to lift, move or secure something, call the professionals at Pro Industrial. Our rigging specialists and sales team are knowledgeable about our products, and we can meet your needs. For a free quote on any of our rigging supplies, please call Pro Industrial today.

Choose the Right Sling for the Job

One of the first tasks when planning your rigging job is choosing the right sling for your application. We carry several types of slings that meet different performance objectives.

| Sling | Price | Flexibility | Weight | Durability | Operator Danger | Scratches | Handling |

|---|---|---|---|---|---|---|---|

| Wire | Medium | Low | Average | Medium | Medium | Very Likely | Difficult |

| Chain | High | Medium | Heavy | High | Medium | Very Likely | Difficult |

| Web | Low | High | Light | Light | Low | Not Likely | Easy |

| Round | Low | Extreme | Light | Light | Low | Most Protective | Easy |

We'll work with you to consider all the important variables.

- What's being lifted

- The size of the load

- How the load will be rigged

- The environmental conditions of the lift site

- The weight of the load.

- The shape of the load

- The angle of the sling

We carry a variety of synthetic slings. They're designed for short-term use below your crane's hook, and they are the most reliable way to handle delicate loads. Our slings are manufactured in the USA.

Wire Rope Slings

Wire rope slings are the most economical option for most lifting applications, and they're the type of sling most frequently used in the industry.

Benefits

- Lighter and less expansive than chain

- Available in longer lengths than any other sling style

- Robust and durable

- Have high temperature limits

Drawbacks

- Not as flexible as some other options

- Much heavier than synthetic slings

- Can deform if bent too far

- Can be challenging to transport and install

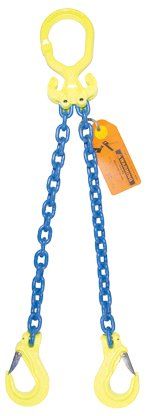

Chain Slings

Chain slings are among the most versatile of the available options. They withstand temperatures and rugged conditions that may damage other slings, and they're flexible and easy to store. Our chains are marked with identification tags that indicate the grade, size, reach, type of sling, working load limit at a specific angle of lift, and serial number.

Benefits

- Resistant to cutting and abrasion

- Flexible for the contours of your load

- Can be fabricated at the length you need

- Safe at temperatures up to 1,000°

Drawbacks

- More expensive than other options

- Heavier to transport, carry, and install

Web Slings

We recommend web slings for loads that are fragile, delicate, or highly polished. They're made of nylon or polyester and have a wide surface area, so they grip securely and have a lower chance of scratching the load.

Benefits

- Provide a tight grip by adjusting to the contour

- Nylon or polyester construction protects the load from scratches

- Wide widths help you control the load

- Relatively low initial cost

Drawbacks

- Vulnerable to sharp edges and abrasive surfaces

- Lose strength if damaged

- Strength can be degraded by harsh environments

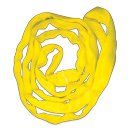

Round Slings

Round slings are constructed with a durable polyester color-coded fabric jacket that indicates the weight capacity. These slings have a large capacity and are relatively inexpensive, and their pliability helps them hug your load better than other options.

Benefits

- Grip securely by conforming to the load's shape

- Low initial cost

- Double wall cover improves sling's life

- Lightweight construction reduces ergonomic issues

Drawbacks

- Vulnerable to sharp edges

- Strength can be degraded by harsh environments

Rigging Hardware

You can rely on Pro Industrial for all your rigging hardware. Our specialists are ready to help you find the right item for your application.

Shackles

Swivel Hoist Rings

Eye Bolts

Below-the-Hook Lifting Devices

For a secure connection between your crane and your load, call Pro Industrial. We carry a wide variety of lifting devices.

Plate Clamps

Beam Clamps

Lifting Beams

Hoists

We're proud to carry hoists for any application. Delivery to your job site is available, so call Pro Industrial today.

Manual Hoists — We offer standard and custom chain lengths, and we can repair and load test all the major brands. For short-term jobs, rentals are available.

Manual Lever Hoists — Our lever-operated hoists are useful for handling, moving, and tensioning a wide variety of loads. We carry chain, wire rope, and web strap models.

Chain Falls — This simple pulley system uses a hand-powered hoist to lift and move heavy loads with ease.

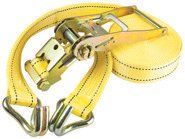

Tie-Downs

Control your load during transport with tie-downs from Pro Industrial. We carry all types of tie-downs that surround, loop over, or attach to your load, and we have the hardware to attach and tighten the tie-downs.

Ratchet Straps

Chain Binders

Ratchet Binders

Lever Binders

Tie-Down Chains

Rigging Training

To ensure that our equipment is used safely, we offer training sessions throughout the year. These programs are ideal for safety managers, construction laborers, salvage and industrial workers, engineers, crane and rigging crews, and all trades. Training can be conducted at our facility or yours. Please call for details.

Rigging Training — Our rigging training program is designed to make lifting operations as safe as possible. We cover maintenance, general rigging, lifting, lifting safety, and the correct use of rigging gear.

- Definitions related to slings, hoists, and rigging gear

- Rigging hardware specifications — identification and selection criteria

- Inspection and removal criteria per OSHA and ASME

- Safe rigging practices

- Factors that affect working load limit

- Proper application of sling protectors

- Knots for tag lines

Signal Training — A rigging operation uses a signal person when the operator does not have a full view of the point of operation, when their view is obstructed in the direction the equipment is traveling, or when site safety requires it.

- Know and understand types of signals used at worksite level

- Competency in using signals

- Understanding the operations and limits of equipment and more

On-Site Rigging Inspections

Make sure your operation is ready to go with on-site rigging repairs and inspections from Pro Industrial. We check safety and compliance, as well as equipment maintenance. We provide you with a report for your files.

Rigging Inspections — Our below-the-hook inspection looks at the lifting beams, and attachments, and we check the web, wire, rope, and chain slings. All items are inspected for OSHA compliance.

Manual Hoist Inspections — We do a pre-shift inspection for OSHA compliance for your hoists, lever hoists, and chain falls.

Harness Inspections — A harness should be inspected before each use, and you can have us provide a detailed inspection every six months and record the results on your inspection record card.

Overhead Crane Inspections — Routine inspections of cranes ensure that their large loads are being transported safely. In compliance with OSHA regulations, we perform a complete inspection at least every 12 months and record the results. Our inspection includes monthly checks of the wire ropes and hooks.

Share On: